Our Competencies

SALES

Our team provides service to our customers by referring to customer satisfaction as a priority. Our characteristics are to analyze the demands and expectations of our customers, to manage our company processes as a customer representative, to provide coordination, to produce solutions and to carry out result-oriented studies.

1

PROJECT MANAGEMENT

Our company processes, which start with effective communication with our customers and end with the delivery of the products to our customers in a timely and complete manner, are managed effectively. We prove this by the increase in yearly sales and the number of customers. The sales team, trusting the power of technical competence from manufacturing, employs its ability to produce relevant solutions in molding while marketing greenhouse products to the whole world.

2

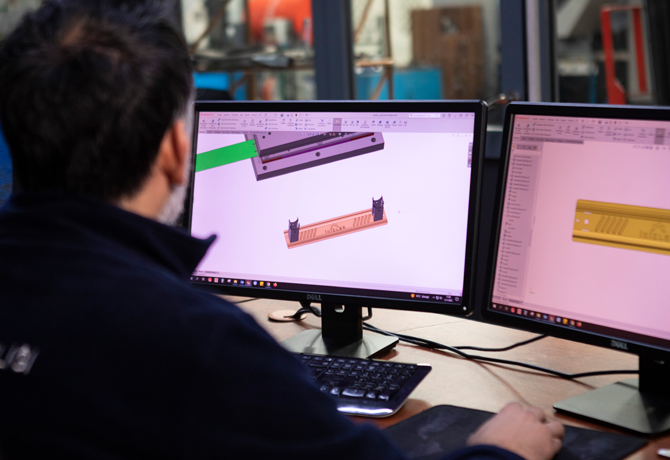

R&D

Design works in İKİZLER KALIP are performed by methods which keep creativity and efficiency at top level, by computer aided design (CAD-CAM) methods such as Solidworks, Esprit at all stages beginning from product concept stage until it becomes final product.

3

PLANNING

İKİZLER KALIP follows all processes over system by specials software in addition to advanced planning system and MRP follow up. IKIZLER KALIP which works with efficiency, quality and sustainability principle lights the way for sector by its team which expands day by day and infrastructure which is renewed continuously. It uses s CRM based special software for export management, for before sales and after sales.

4

MOLD PRODUCTION

Coordination between CAD-CAM methods and modern CNC machines was maintained in mould manufacturing unit for producing designed part at same quality and transferring design to mould as exactly as it is in İKİZLER KALIP. All mould requirements which are used in manufacturing are prepared in mould manufacturing division within İKİZLER KALIP.

5

SERIAL PRODUCTION

All products which were delivered from steel sheet raw material storage and passed through quality approval are processed in our pressing room in steel sheet forming process. Test trials are performed over designed mould firstly in molding room and then in pressing room. Casette and rod, which is used for greenhouse opening, greenhouse suspension ball, greenhouse connection equipment and greenhouse materials for special designs are produced by expert personnel and new technologic machine park in pressing room.

6

REDUCER PRODUCTION

As İkizler Kalıp, we produce our reducers used for the greenhouse sector with our high technology machine park and our competent staff. Our high-quality control process, which starts at the input of raw materials, accompanies the production of the product with the highest quality and the operation of the ventilation systems of greenhouses and livestock buildings in every region of the world.

7